Posted on 24 May 2024

Steelmaking industries include sophisticated, multi-physics processes, among others. Steel manufacturing processes are operated by human operators who possess certain qualification before they can be accepted to run the processes. Artificial intelligence (AI) can assist many processes to complete the tasks remotely.1

The Importance of AI

Technology is constantly evolving every day. Manufacturing industries such as steel, are continually implementing AI into their daily operations to boost productivity, health and safety, reduce operating costs, and gain other advantages.2

Steel Industry in Southeast Asia

Presently, Southeast Asia countries are dealing with overcapacity issues. The current capacity stands at 72 million tonnes per year. During the fourth quarter of 2022, six blast furnaces closed in Vietnam. Alliance Steel, a Chinese investment had experienced slowdown. The Philippines steel industry project such as the Chinese conglomerate HBIS showed no progress and is likely to be cancelled.3

Usage of AI in Steel Industry

AI is used in a wide range of industries, including advertising, customer support, and e-commerce. AI aids in the development of business solutions.

Steel is one of many industries use to spur productivity and innovation.4

How AI is used to make the steel industry more sustainable

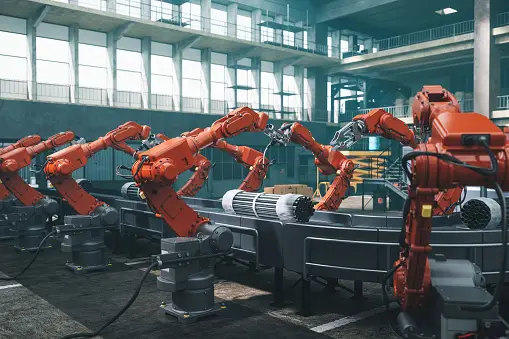

The application of AI in the steel industry has opened the door for smart factories. AI can conduct operations which eliminate human errors. This will also ensure safe working environment for employees.5

Businesses can use AI algorithms to find patterns, predict market trends, and streamline production procedures. Manufacturers will benefit from this in terms of demand forecasting, inventory management, and maintenance scheduling. 6

The steel supply chain necessitates prompt decision-making and efficiency. Supply chains are optimized by taking into consideration market demand, inventory levels that require massive volumes of data. Coordination between producers, suppliers, and customers will also be made possible by AI. 7

iV. Defect Detection and Quality Control

Product quality is an important segment in the steel industry. Ways to detect defects include usage of computer vision and machine learning techniques. 8

V. Customer Relationship Management

Customer relationship management (CRM) technologies driven by AI assist steel producers in enhancing customer experiences. This foster enduring partnerships. 9

Challenges

Usage of AI to improve steel production is not a walk in the park. It is complex. Steel producers will need to bring in experts to streamline procedures. The Steel industry has far more complex supply chain organization when using AI.

Creation of steel require other ingredients which need more processing time. Usage of different iron ores can produce low steel grade to meet customer’s expectation.

Every production that is halted will cause problems to the output quality. There is a need for constant supply of materials to avoid machinery restarting costs. 10

Conclusion

Artificial Intelligence (AI) is developing rapidly and has the potential to assist in resolving many issues facing the steel sector. There will be difficulties throughout the transition. However, steel businesses must begin utilizing AI as it is widely accessible. AI is here to stay. The steel fraternity has to embrace it!

Source:- 1,10 wizata.com, 2022

2 dailypioneer.com, 2023

3 gmk.center, 2022

4,5,6,7,8,9 equitymaster.com, n.d

Source:SEAISI