Posted on 23 Nov 2023

Electric Vehicle (EV)

Electric Vehicles (EV) are partially or fully powered by electric power. They are environmentally friendly, requiring little petrol or diesel. Two types of electric vehicles are battery electric vehicles (BEV) and plug-in hybrid electric vehicles (PHEV).1 EV can range from cars and transit buses to trucks, tractors, and trailers.

Demand for steel in the world is projected to increase from 1,951 million tonnes (MT) in 2021 to 2,500 (MT) in 2050.2 Petrol-driven vehicles are expected to disappear on the road one day. As the world is experiencing climate change, demand for low emission commuting, support from the government through subsidies and tax rebates have made manufacturers switch to electric vehicles. Across Asia Pacific, electric vehicles are expected to grow gradually while the North American and European market are experiencing faster growth.3

As manufacturing steps up, the materials that are used in the process increase too. The materials being used to manufacture electric vehicles include electric motors, battery cells & packs.

The advances in making high strength steel allows the EV to become lighter and steel makers will continue to explore ways to make steel stronger over time.

Usage of steel in an electric vehicle are as follows: -

i. Electric Motor

In the manufacturing of electric motors, electric steel is widely used. In essence, the rotor is the material that produces an electromagnetic field. Steel manufacturers focus on making electric steel magnetically-soft, tougher, and thinner.4

ii. EV Body

Steel will continue to play an important role in the design of EV vehicles. The construction of one EV vehicle needs high-strength steel as they can reduce weight by 25%-39%. This will also help to save up to 4.5 tonnes of greenhouse gas emissions.

iii. Components in EV Battery

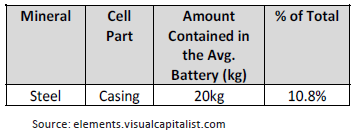

An electric vehicle needs a good battery to run smoothly. An EV battery consists many components such as graphite, aluminium, nickel, copper, and others. Steel is being use in the casing for battery.

Benefits of Stainless Steel for Casing

iv. Safety

From the safety angle, steel can provide heat resistance thus safeguarding passengers in case of fire outbreaks. Steel has 3 to 4 times tensile strength compared to bamboo and yet is deformable to absorb impacts. Modern joining technologies

such as laser welding reduce tension in bonded metal parts. This will enhance safety when accidents occur.6

v. Eco-Friendly

Electric cars can be viewed as environmentally friendly. Carbon emissions can be reduced by charging with green energy. Driving becomes more environmentally friendly as they are generated by hydropower, solar, wind, and low carbon energy sources which will result in cleaner environment. Although carbon footprint still exists in EV, the amount is not as high as a gasoline vehicle.7

Climate Change

As climate change continues to cause severe shifts in weather patterns, this has led to growing awareness in environmentally friendly vehicles in everyday usage.

Sales of EV

In 2022, around 10 million electric cars were sold globally. This year, the figures are expected to increase to 14 million. The largest market for EV is China, Europe, and the United States. In 2030, sales are expected to rise to around 60%.8

Electric vehicles will be the automobiles of the future. Steel will remain as the preferred materials for body structures and battery casing as it contains strength and flexibility. This combination is suitable to produce EV with cost efficiency and maximizing vehicle driving range with a single charge.9

Sources:

1 twi-global.com, 2023

2 Global Efficiency Intelligence, 2023

3 marketsandmarkets.com, 2023

4 voestalpine.com, 2022

5 outokumpu.com

6 ffamericas.com, 2023

7 greenly.earth

8 iea.org

9 steel.org

Source:SEAISI