Posted on 30 Jun 2022

The development of the industrial sector has contributed significantly to the development of society and economic growth in the world. However, the development of this sector also brings problems with the emergence of climate change issues and carbon emissions that can damage the environment.

With the increasing intensity of decarbonisation and also the net zero carbon targets to be achieved in 2050, the industrial sector must certainly be one of the central points in the transition towards clean energy and reducing carbon emissions.

The industrial sector commonly uses fossil fuel/hydrocarbon as a source of energy to generate power necessary to run operations. These fuels react with oxygen at high temperature, and the chemical reaction generates energy and carbon dioxide, which is released to the atmosphere as “carbon emission”.

Many efforts have gone into reducing the amount of carbon emission from the industry, such as increasing process efficiency, the usage of alternative-cleaner energy source, and application of Carbon Capture, Utilization, and Storage (CCUS). The last one, has been done by directly capturing carbon dioxide.

Carbon Capture, Utilization (or sometimes this is termed “Usage”),

and Storage or in short CCUS means literally capturing of carbon dioxide before it is released to the atmosphere, storing it in the safe storage (usually underground), and utilizing it for another purposes. This way, it directly remove the presence of CO2. Thus, it has key role to play in decarbonisation and the challenge of global climate change.

How to capture CO2?

The first step to take in the case of CCUS, is to capture the CO2. Fossil fuels such as coal, oil and natural gas have energy stored within. To release this energy, there is a need to have a chemical reaction between fossil fuel and oxygen in form of combustion (burning) and conversion process. The result of this reaction is energy and CO2 as by product.

In systems where the coal is pulverised to powder, which makes up the vast majority of coal-based power plants through North America, Europe and China, the CO2 must be separated at diluted concentrations from the balance of the combustion flue gases. In other systems, such as coal gasification (where coal is converted to chemicals, natural gas or liquids), the CO2 can be more easily separated.

There are three basic types of CO2 capture: pre-combustion, post-combustion and oxyfuel:

1. Pre-combustion

Pre-combustion capture refers to removing CO2 from fossil fuels before combustion is completed. It can also involve converting fuel into gaseous mixture of Hydrogen and CO2. For example, in gasification processes, a feedstock (such as coal) is partially oxidized in steam and oxygen/air under high temperature and pressure to form synthesis gas. This synthesis gas, or syngas, is a mixture of hydrogen, carbon monoxide, CO2, and smaller amounts of other gaseous components, such as methane. The syngas can then undergo the water-gas shift reaction to convert CO and water (H2O) to H2 and CO2, producing a H2 and CO2-rich gas mixture. The concentration of CO2 in this mixture can range from 15-50%. The CO2 can then be captured and separated, transported, and ultimately sequestered, and the H2-rich fuel combusted.

2. Post-combustion

This process separates CO2 from combustion exhaust gases by using a liquid solvent or other separation methods. In an absorption-based approach, once absorbed by the solvent, the CO2 is released by heating to form a high purity CO2 stream. This technology is widely used to capture CO2 for use in the food and beverage industry.

3. Oxyfuel combustion

This process uses oxygen rather than air for combustion of fuel. This produces exhaust gas that is mainly water vapour and CO2 that can be easily separated to produce a high purity CO2 stream.

Once captured, CO2 will be transported using ship, road or pipeline in a liquid or gas state to the suitable storage location. From there, CO2 will be pumped underground or under seabed into the storage area, often at depth of over 1 km if it is not used on the site. CO2 can be stored in depleted coalbeds or oil and gas reservoirs or in deep saline aquifers where the geology for storage is suitable. This prevents the CO2 from entering the atmosphere, mitigating against carbon emissions from industry, and thereby reducing the contribution to global warming and ocean acidification.

In CCUS, the CO2 can also be utilised for another purpose instead of only being passively stored. Innovative new technologies can transform captured carbon in a variety of valuable uses such as chemicals, synthetic fuels, and the production of construction materials.

Based on the report from International Energy Agency (IEA), in 2019, around 230 million tonnes (Mt) of CO2 are used each year. The largest consumer is the fertiliser industry, where around 130 MtCO2 per year is used in urea manufacturing, followed by the oil sector, with a consumption of 70 to 80 MtCO2 for Enhanced Oil Recovery (EOR). CO2 is also widely used in food and beverage production, the fabrication of metal, cooling, fire suppression and in greenhouses to stimulate plant growth.

More than two-thirds of current global demand for CO2 comes from North America (33%), the People’s Republic of China (“China”) (21%) and Europe (16%), with the demand for existing uses expected to grow steadily year-on-year.

CCUS Project Around the world

Increasing awareness of climate change and also targets of net zero carbon by 2050 has increased interest in CCUS project. IEA noted in their Technology Report that until 2021, CCUS facilities around the world have the capacity to capture more than 40 MtCO2 each year. Some of these facilities have been operating since the 1980s, when natural gas processing plants in the Val Verde area of Texas began supplying CO2 to local oil producers for enhanced oil recovery operations. Since these early projects, CCUS deployment has expanded to more regions and more applications.

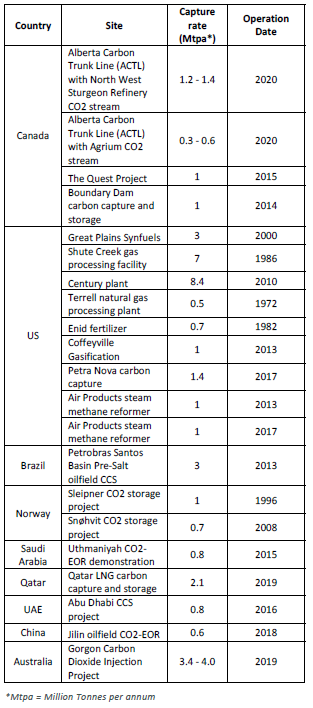

The first large-scale CO2 capture and injection project with dedicated CO2 storage and monitoring was commissioned at the Sleipner offshore gas facility in Norway in 1996. The project has now stored more than 20 MtCO2 in a deep saline formation located around 1 km under the North Sea. This is the list of CCUS Project around the world as mentioned by IEA:

CCUS Challenge in the future

The biggest challenge for CCUS Technology for today is of course from the angle of economics. Storing CO2 at such scale is a pure cost, and related investments have (understandably) been limited, given the absence of regulatory incentives to defray the installation of capture technology and a storage infrastructure. There are also the tricky legal issues, such as liability for potential leaks and the jurisdictional complexities associated with underground property use.

Mckinsey noted, in their reports, that to reach CCUS’s potential, commercial-scale projects must become economically viable. In the short to medium term, CCUS could continue to struggle unless three important conditions are met: (1) capture costs fall, (2) regulatory frameworks provide incentives to account for CCUS costs, and (3) technology and innovation make CO2 a valuable feedstock for existing or new products.

References :

https://www.iea.org/reports/about-ccus

https://www.meti.go.jp/english/policy/energy_environment/global_warming/roadmap/innovation/ccus.html

https://www.nationalgrid.com/stories/energy-explained/what-is-ccs-how-does-it-work

https://www.twi-global.com/technical-knowledge/faqs/what-is-carbon-capture-and-storage

https://www.aiche.org/ccusnetwork/what-ccus

https://www.globalccsinstitute.com/archive/hub/publications/191083/fact-sheet-transporting-co2.pdf

Source:SEAISI